Our SOCON have an experienced R&D technical team that can develop non-standard products that meet customer needs in a short period of time, provide various personalized technical services, optimize product technology for different applications, provide customers with high-quality products and services with leading technology, and grow together with customers and succeed hand in hand.

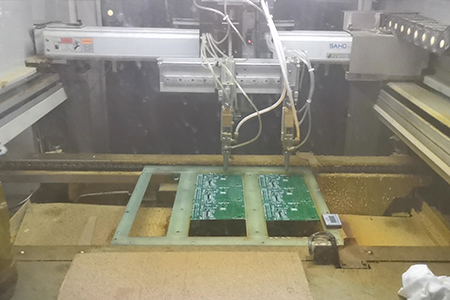

SOCON workshop has introduced and used single-board automatic testing equipment such as ATE to test each control board, driver board and other PCB boards. A total of 4 automatic production lines have been set up, which greatly improves the average daily production efficiency. The production efficiency is more than double that of the traditional production method, and the one-time pass rate can reach 99.9%.

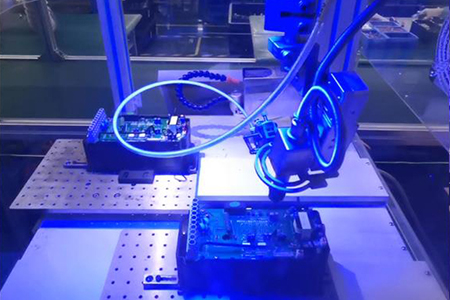

The circuit board of SOCON after ATM intelligent detection will go through the steps before assembly through automatic painting and drying equipment. 2 automatic painting and drying production lines have been set up to reduce the shortcomings of uneven and incomplete spraying caused by artificial painting, and greatly improve the quality of products.

SOCON production lines adopt advanced automation process and excellent technological workmanship. It is equipped with optical mirror AOI contrast mode to achieve automatic inspection, PLC and IPC integrated equipment to realize automatic test and classification, the leading ESOP management system to ensure the uniformity of product and improve product reliability and so forth.

Driven by science and technology, develop by quality. All SOCON products should go through strict quality control procedures, aging test at 50℃ for 24H, so that users can use each inverters with more peace of mind. Improve the quality awareness of employees to ensure continuous improvement of product quality. Provide customers with the best products and services to improve customer satisfaction.

After the "Aging Test" is completed, the second full-automatic full load test is carried out. The load motor is adapted to the inverter of the full power range, multiple sets of adaptive motors are used to fully test the quality of each unit to ensure the reliability of the product. Avoid the problem of virtual soldering of IGBT or other components after aging, so that users can use it with more peace of mind, Adhere to quality first.