一、Load Characteristics

1. As far as the principle of compressing gas is concerned, the screw compressor, like the piston compressor, belongs to the volumetric compression machinery; in terms of its movement form, the rotor of the compressor is the same as the power machinery, which performs high-speed rotating motion. Therefore, the screw compressor has the characteristics of both.

2. The screw air compressor is composed of a pair of male and female rotors (or screws) that are meshed with each other in parallel and rotate in the cylinder, so that the air between the rotor tooth slots continuously produces periodic volume changes, and the air moves along the axis of the rotor. It is transported from the suction side to the output side to realize the whole process of suction, compression and exhaust of the screw air compressor.

3. The screw compressor has a high addendum linear speed, and the speed can reach more than 10,000 revolutions per minute, so it can often be directly connected with a high-speed driving machine. Therefore, its volume, mass, footprint and exhaust pulsation per unit displacement are much smaller than those of piston compressors. Screw compressors do not have wearing parts such as air valves and piston rings like piston compressors, so they are reliable in operation, long in life, and easy to realize remote control. In addition, since there are no reciprocating parts, there is no unbalanced inertial force (moment), so the screw compressor has a small foundation and can even operate without a foundation.

二、Inverter Application Requirements

1. No impact on the power grid: the motor is controlled by a frequency converter, which realizes a real soft start, and there is no impact current during the start-up process;

2. The control precision of SOCON SC500A series inverter is relatively high, which makes the motor have high speed control precision in the whole control process, so that the output pressure of the air compressor is more stable, and the pressure fluctuation is controlled within 0.03MPa;

3. Energy saving: In the original power frequency control mode, the air compressor is often in unloaded operation, resulting in a great waste of energy. The frequency converter is used to adjust the motor speed in real time to realize output constant voltage control and avoid energy waste during unloading;

4. Reduced maintenance: The motor is controlled by frequency conversion, and the motor realizes a real soft start. During the soft start, there is no impact on the equipment, which reduces the maintenance of the equipment in the later stage.

三、Commissioning Guide

1. On-site pictures:

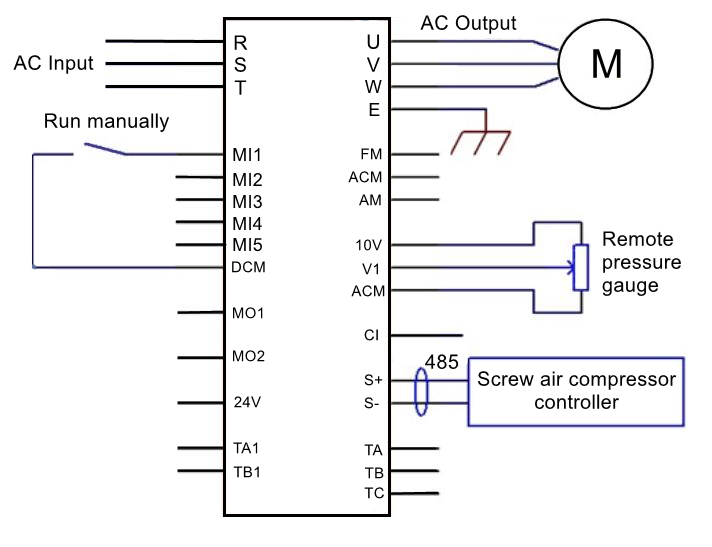

2. Wiring diagram:

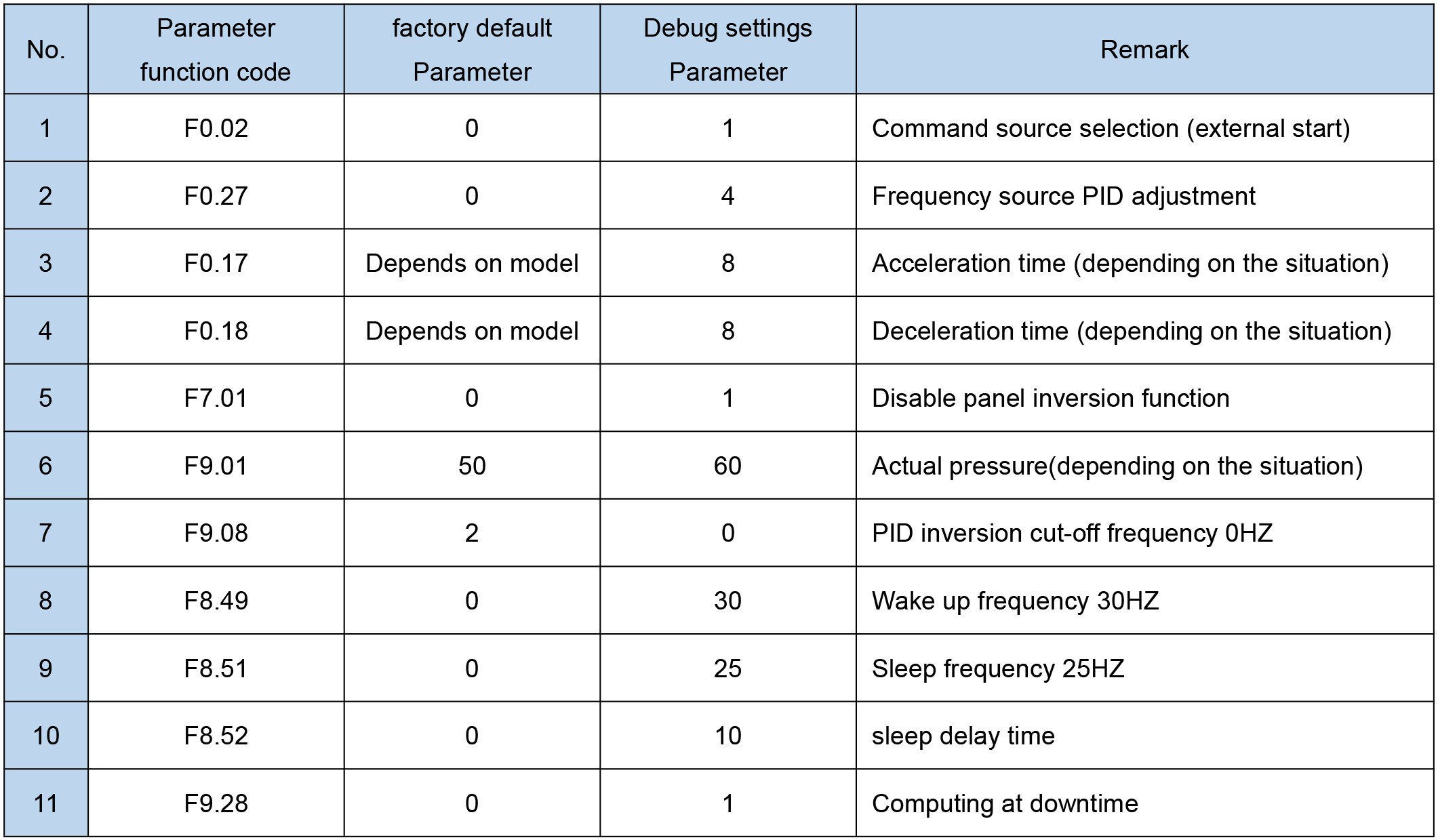

3. Parameter description: (take 55KW motor as an example)

四、Matters Needing Attention

1. When setting the sleep frequency, it must be lower than the wake-up frequency value;

2. Do a good job of dust prevention measures, and users must regularly clean and maintain;

3. The reverse function must be prohibited.