一、Load Characteristics

Large circular knitting machines are widely used in the textile industry. Generally, they are started externally, and the speed is adjusted by an analog signal source. They can also be controlled by a single-chip microcomputer or PLC+text controller; the load speed is high, the starting torque is high, and it often stops suddenly.

二、Requirements for Inverter Application

Larger low-frequency torque (the load is heavier when weaving); quick start response; smooth motor operation during work; soft and accurate stop, no reverse and rotation.

三、Debugging Guide

1. On-site pictures:

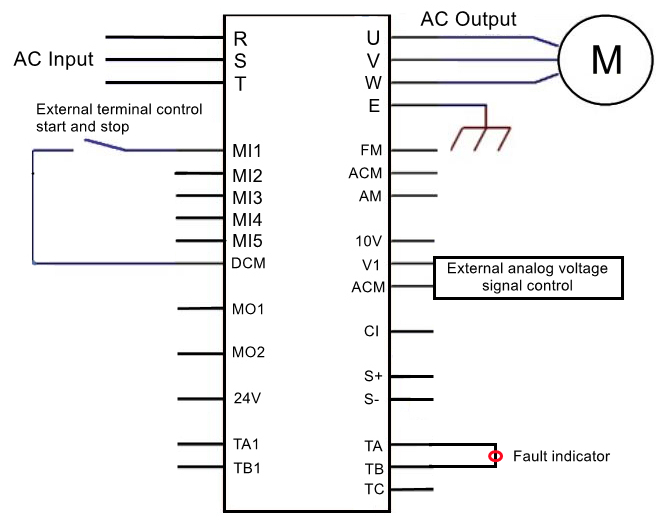

2. Wiring diagram:

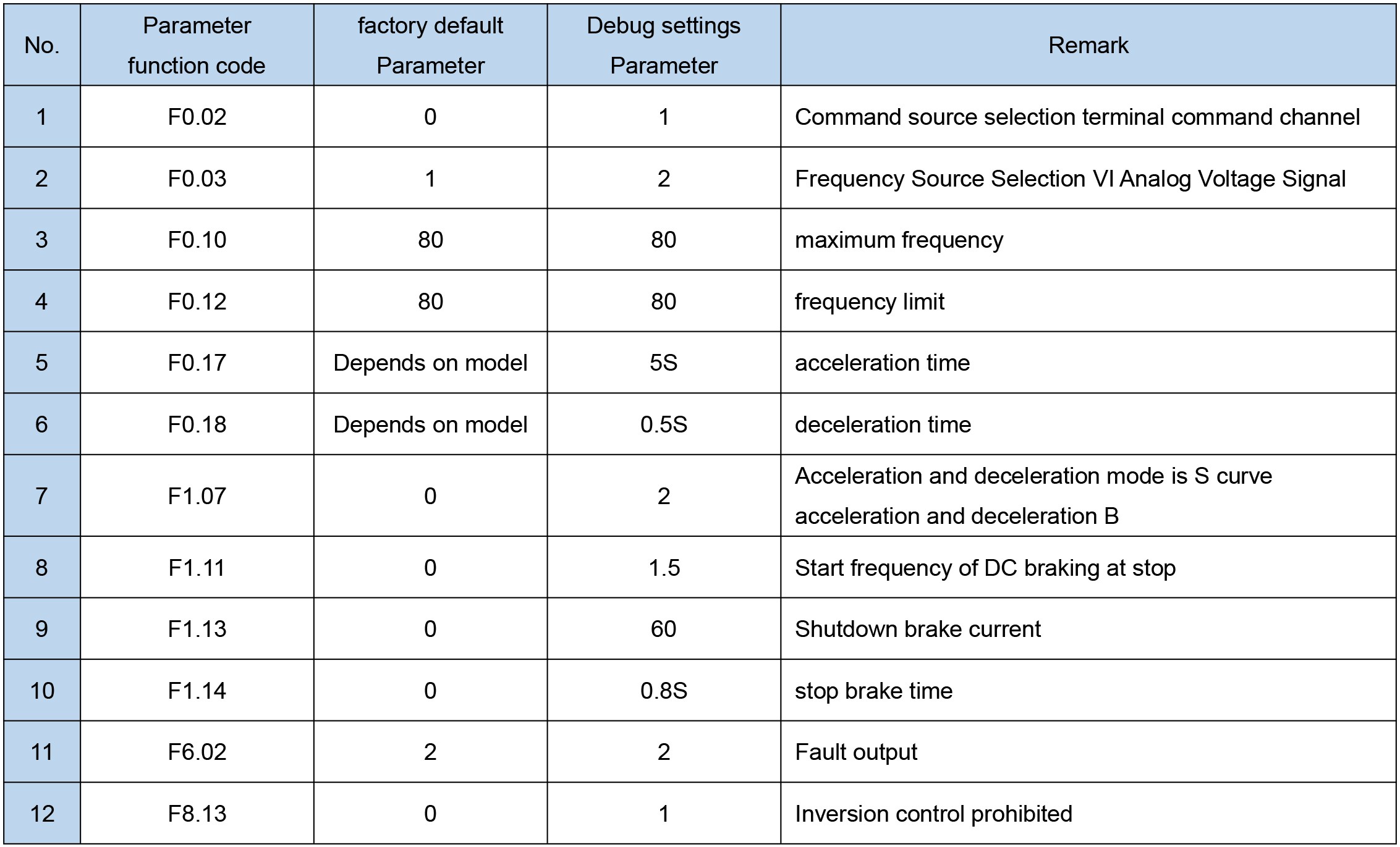

3. Parameter description:

四、Matters Needing Attention

1. Remove the load of the motor before running, and stop the motor after confirming the running direction of the motor. If the direction is reversed, the wiring positions of any two of the three-phase output lines can be exchanged.

2. Special attention should be paid to the slight reversal of the motor when it is stopped. The DC braking parameters of the frequency converter and the S-curve parameter group can be adjusted appropriately. A slight reversal can also damage the needle disc of the circular knitting machine; regular cleaning and maintenance, pay attention to ventilation Heat dissipation.