一、Load Characteristics

1. The host of the plastic granulator is an extruder, which is composed of an extrusion system, a transmission system and a heating and cooling system; the energy saving of the plastic granulator can be divided into two parts: one is the power part, and the other is the heating part. Power part: Most of them use frequency converters. The energy-saving method is to save the remaining energy consumption of the motor. For example, the actual power of the motor is 50Hz, but you actually only need 20HZ~40Hz in production. It is wasted in vain, the frequency converter is to change the power output of the motor to achieve the effect of energy saving; the heating part is energy-saving, and the heating part is mostly energy-saving by electromagnetic heating.

二、Inverter Application Requirements

1. Strong overload capacity and large low-frequency torque;

2. High speed precision and simple control

3. V/F mode control, good heat dissipation performance

三、Commissioning Guide

1. On-site pictures:

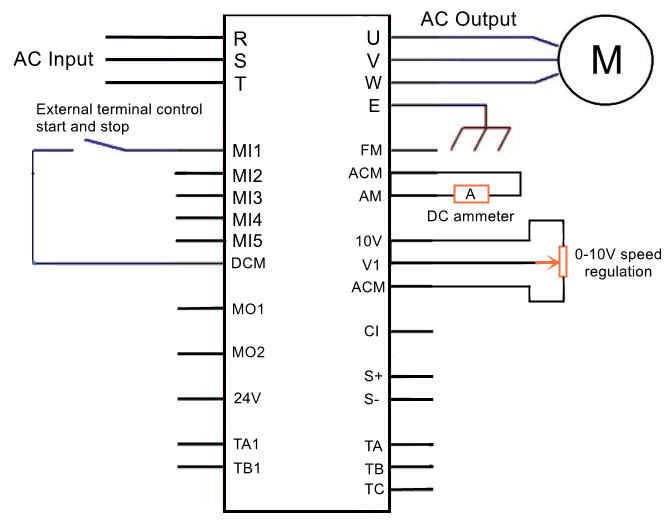

2. Wiring diagram:

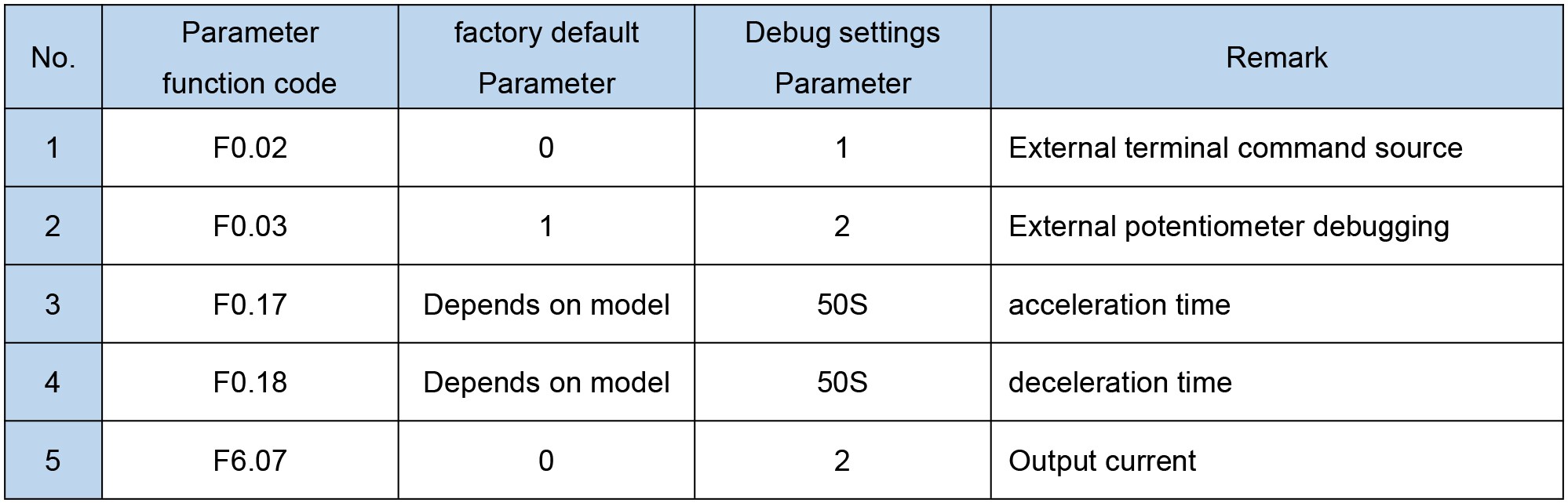

3. Parameter description: (take 55KW motor as an example)

四、Matters Needing Attention

Take measures to prevent heat dissipation and clean and maintain regularly.